Relative Humidity

The relative humidity of the air is the RATIO of the actual amount of moisture in a volume of air versus the saturated amount of moisture in that volume.

Expressing this in more detail, we can say that relative humidity, RH, is a measurement expressed as a percentage of the moisture content relative to the amount of water, which that body of air could hold, if saturated at the same temperature and pressure.

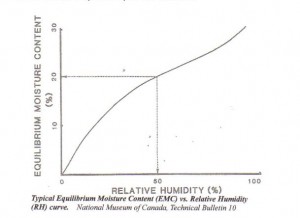

Most substances contain a certain quantity of water, which is determined by the relative humidity of the surrounding air, or ambient conditions. For any given RH condition, a substance has precise and specific moisture content when it is in equilibrium with the surrounding air. This equilibrium moisture content (EMC) of any material is the ratio of the water it contains to the dry mass of the material expressed as a percentage. For each RH condition, a given material has corresponding equilibrium moisture content. This can be represented by an ECM curve.

To protect the artifact, the equilibrium moisture content must be kept constant. This requires both stable temperature and relative humidity levels.

When at equilibrium, the differential vapour pressure of the moisture content in the artifact and the relative humidity of the surrounding air is ZERO, meaning that the water molecules are not moving from the artifact to the surrounding air, or vice versa. It is vapour pressure that is the driving force to move water molecules one way or the other.

The most common damaging effects of a continuous change of moisture content in an artifact are:

- Cracking or splitting of wooden objects

- Flaking of coatings (such as paint) on coated objects

- Mold developing on certain organic objects

- Efflorescence of pottery

- Corrosion of metal objects

To protect from any of these possible environmental damages, in addition to preventing people from touching or handling the artifact, it can be encapsulated in a sealed enclosure thus creating a Micro Climate.

What is a Micro Climate?

A micro climate is generally the condition inside an enclosed space, insofar as it differs in temperature, humidity and air cleanliness from the surrounding ambient. With regards to humidity, the required parameters for a museum display case are a constant, non-cycling level of relative humidity that is maintained within the conservator’s set parameters.

In the past, it was difficult for the conservator, or curator, to establish the proper stable environment that is required for certain artifacts, since the choices were very limited.

Today, a large amount of literature is available, as well as new technologies, aiding in the decision. Each artifact has to be judged for its sensitivity to temperature, relative humidity, light, and dust (pollutants). Once it has been decided that humidity controls are essential for the preservation of the artifact, a decision has to be made as to how it can be accomplished.

How to Accomplish Relative Humidity Control

There are basically three choices from which to select:

A) Whole Building HVAC System

B) Passive System

C) Active System

A) The HVAC System

Using the Building HVAC System, artifacts inside of an enclosure are subjected to the same conditions as the ambient. Basically, this subjects the artifacts to the same temperature and humidity conditions as the building environment.

The building HVAC system is usually only designed for human comfort. In the winter, you have to heat and humidify, while in the summer one has to cool and de-humidify. In the fall and spring, these variable conditions can all occur in a single day, making it extremely difficult for the system to respond quickly. In addition, especially during this energy crunch, building maintenance likes to reduce the temperature of the building during the night to save money. This may cause additional stress to the artifacts.

Other factors that can affect the ambient conditions in the building are:

- open doors or windows

- extremely fast load changes caused by large numbers of visitors (especially on a rainy day)

- rapid environmental changes, especially in the transfer seasons of spring and fall

To maintain an even temperature and RH, elaborate controls and equipment are required. These systems are slow to respond, especially in the spring and fall, when rapid ambient temperature and humidity changes occur.

For existing older buildings, it can be very expensive in capital and operating cost, to try to maintain stable temperature and humidity conditions. In most cases, major modifications to the existing building and HVAC systems will be required. For new buildings, the accuracy to protect the artifact (even at -/+ 2ºC and -/+ 3% RH) is extremely expensive, requiring leak proof ducts, top quality filtration, and elaborate up and down RH controls.

In summary: all artifacts in the enclosures will be at the same variable temperature and RH conditions as the ambient.

B) Passive Systems

A passive system, otherwise called a desiccant system, basically utilizes silica gel or a similar medium as a buffer material. Silica gel has been utilized since the 1950s for this purpose. The medium is conditioned, or regenerated, to produce the required humidity inside of an enclosure. No mechanical air movement is employed, so this is effectively a static system.

For the silica gel buffer to be effective, it has to meet the following requirements:

- Have a high capacity either to release or to absorb water (such gels will have a relatively high moisture content around the desired RH level. That is, the EMC vs. RH curve will have a steep linear slope near the desired RH so that large EMC changes correspond to lesser RH changes).

- Must offer a large surface area to allow a rapid rate of buffering.

- Must not suffer any physical damage when it absorbs and desorbs water.

- Must remain dry to the touch even with a high moisture content.

- Must be able to condition and regenerate.

- Must be re-usable.

When silica gel is employed for micro climate controls, the following decisions must be made:

- the type of silica gel required for your particular application

- the amount of silica gel required for a particular enclosure, rule of thumb is 20 kg/1m3 of display case volume

- the methods of accurately conditioning silica gel

- the type of well-sealed enclosure required to house the silica gel so that is can be removed and replaced when conditioning or regeneration is required

- adequate apertures above the silica gel into the inside of the enclosure

- providing a very well-sealed enclosure for the artifact contained inside of the case environment

The desiccant can be contained in cheese cloth bags or loosely placed in a removable tray. The surface of the gel has to be exposed to the interior of the enclosure, which will normally place the gel in the bottom of the display case enclosure.

The artifact has to be contained in an extremely well-sealed enclosure to minimize the effects of ambient humidity on the enclosure exhibit space. Furthermore, the enclosure needs to be designed or an existing case must be modified for the extra weight, volume, and accessibility to place and remove the silica gel. For long term stability and a minimum amount of maintenance (no more than twice a year), the enclosure should be opened rarely and the gel spread out in this layer for maximum exposure.

This system is very slow to respond to changes in ambient temperature.

In taller display cases, stratification (e.g. RH layering) can be a problem. In addition conditioning and regulating silica gel is labour intensive and requires specialized equipment.

In summary: Only artifacts in very small, very well sealed cases can be protected.

C) Active Systems

An active system uses an external electro /mechanical generator connected by hose(s) to an enclosure. The generator continuously supplies and monitors the required RH to the enclosure.

The active system of climate control, if designed properly, responds very quickly to changes in ambient temperature and relative humidity.

The artifact can be contained in a moderately well sealed enclosure. However, the sealing requirements are not nearly as stringent as those required for the passive system, if the system is designed with ample capacity.

In general, there are two types of active systems available:

- A small unit for individual display case(s) to a total volume of 8m³. This unit is most often located in the bottom of the display case, and connected to the upper display space by small hoses. A sensor inside the display space case continuously monitors the required RH. The enclosure needs to be designed or modified for placement of the climate controller and/or air supply hoses. The individual micro climate generator requires a 120 VAC outlet as well as adequate ventilation.

- A large unit for an entire gallery of display cases, period rooms or storage space up to a total volume of 200m³. This unit is most often located in a mechanical room, or a large closet, where the required utilities are present (i.e. water supply, 240 volt hook –up and floor drain). A network of small air supply piping connects the large unit to each individual display case. This unit will fully compensate for the temperature fluctuations in the gallery.

The capacity of both the small and large active systems are very much dependant on the construction of the display volume (e.g. display case). Much has been written about “well-sealed” display cases. What is the definition of a “well-sealed” display case, and can leakage rate be measured? A leakage rate of 10% or less of a case volume over a 24 hour period is attainable in new display cases only, and only in small display cases ( i.e. 5m³ or less). These cases are often very expensive and allow for very little access or movement. More realistic for the majority of existing display cases is a leakage rate of two to four case volumes over a 24 hour period.

To make an educated decision regarding method of controlling the enclosure, as well as the capacity required, the leakage rate (commonly referred to as air exchange rate (AER) should be established. In addition a choice should be made if the conditioned air from the Micro Climate unit should be recirculating or positive pressure.

The recirculating type unit continuously removes a fixed quantity of air from the display volume conditions the air and returns the same air back to the display case. Micro Climate Generators adopting this type of system generally have a much larger air capacity and require much less water supply, less water drainage and overall much less maintenance.

The positive pressure type unit takes a very small quantity of gallery (ambient) air and conditions this air as required and deliveries it to the display case. The air will pressurize the case and exits from the case though the leaks (or intentional exhaust opening) form the display case. These types of units have a very small capacity and are high maintenance for water supply, water drainage and air filtration.

An excellent article titled: “Simple methods to measure air exchange rates and detect leaks in display and storage enclosures” written by Andrew Calver and Andy Holbrook and co-authored by David Thickett and Steven Wintraub, can be found at www.cwaller.de/vitrinentest/calver2005_air_echange.pdf

In its conclusion the authors state:

“We have shown that the AER of enclosures, an important factor for preventive conservation, can be easily calculated using low cost gas detectors. “

More and more case manufacturers are starting to use test methods to comply with the required specifications.

An overview is attached comparing the three most popular small micro climate generators, which are available at present.