Museum collections are one of a kind and contain some of the most cherished and valuable treasures around the world. It is apparent that these collections must be kept under the safest, most stable and well controlled environmental conditions possible in order to preserve them. The best conditions for an artifact are a stable temperature, safe light levels and, the hardest condition to control, a stable relative humidity (RH). There are a couple ways to regulate relative humidity, but using silica gel is the most widely encountered and well known methods out there.

Silica gel is an inert, porous, non-crystalline, granular form of silica, comprised of silicon and oxygen. The gel has a high absorptive capacity for water vapor, making it a good buffering agent, absorbing not only water, but some airborne pollutants as well. Silica gel is good to use, as it is non-deliquescent, non-corrosive, stable, and compatible with most other materials. Silica gel can be used both as a drying agent and as a moisture releasing agent, to removing moisture from the air as the former and adding moisture to the air as the latter. For both of these purposes, silica gel must be conditioned before its insertion into a display case. The processes of preparation, conditioning and maintenance are very import and is vital that museum staff know how to properly carry out these procedures.

Silica gel can be kept for a long time without fear of exceeding its life span in which it can still be used. This being said, purchasing a large supply and then storing some for later use can be a good idea. There are many different grades of silica gel that can be used in display cases without a problem. The rates of absorption and desorption only vary slightly for the different grades, the rate differences are so slight that it is not significant for most gels.

Some types are indicating silica gels, and are coated in cobalt salts which change the colour of the gel according to its moisture content. These types of silica gel are blue when dry and become pink when saturated. Although the gel is non-toxic, it does give off a fine silica dust when being moved from one container to the next which can be harmful and cause irritations. In order to minimize the risks when handling silica gel, dust-filtering masks and gloves should be worn.

As a humidity buffer, dry silica gel can reduce humidity fro m an humid enclosure by exposing it for a certain amount of time and vice versa for drier enclosures. For any given RH, silica gel has a corresponding moisture con tent when it is in equilibrium with the atmosphere around it. The equilibrium moisture content (EMC) of a substance is the ratio between the mass of water that the substance contains versus its dry mass, shown as a percentage. Silica gel is a good humidity buffer because of its large amount surface area, allowing the gel to have a rapid rate of buffering; its high capacity for absorbing and releasing water; its resilience to physical damage as it absorbs and releases water; the gel is still dry to the touch even if it has a high moisture content; and the gel is reusable and easily conditioned.

Silica gel is a great buffer, because it can be reused many many times after it is first purchased and used. Before each use however, it must be reconditioned to meet the moisture content requirements of the case it is buffering. There are a couple different ways to condition silica gel, and a few of them will be described. When conditioning the silica gel, you must ensure that the moisture content of the gel is the same as the EMC at the specified RH you are using it for. This value is determined by using the EMC vs. RH curve for the specific gel that you are using.

Conditioning Silica Gel

There are four main steps to go through when conditioning the gel: drying the gel, determining the amount required for the case it is buffering, weighing out the gel, and adding moisture to the silica gel.

To begin conditioning the gel, you must first make sure that it is completely dry in order to weigh it and obtain the dry mass of the silica gel. To dry the silica gel, spread it in shallow pans and heat it at 120ºC for a minimum of 12 hours. After the gel has been heated, place it in metal containers immediately and seal it tightly to ensure that it will remain dry. Weigh the amount gel after it has cooled.

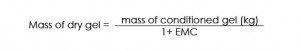

The next step is to figure out the amount of gel you need, to make sure that you do not have too much or too little. Too much silica gel would require an excessive amount of space needed to house it, and add additional costs when designing and building the case. Too little will not have the needed capacity to buffer the enclosure on a long-term basis with a fluctuating RH. The general rule of thumb for a well sealed case, is to use 20 kg of conditioned silica gel for every cubic meter of volume in the display case. Following this recommendation, the case can be kept in a 35% to 65% RH range using silica gel. To determine the amount of conditioned gel that is required, multiply the case volume by 20. After you have done that, you can figure out the corresponding EMC of the specific gel you are using at whichever RH the silica gel will be used to maintain (using the EMC vs. RH graph). With these pieces of information you can figure out the mass of dry silica gel you need by using this formula:

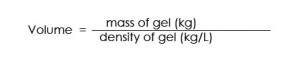

Once you have this information, the volume of the required silica gel can be determined by using this formula:

Now the silica gel can be weighed out to the specific amount that is needed for conditioning. To condition the gel, either permeable, heat-resistant bags or screen-trays can be used to hold the silica gel. Using bags to condition the gel is easier for handling and reusing the gel, since you can condition the silica gel in the bags and just insert the same bags into the enclosure it is buffering.

Before putting the gel into its container, weigh the empty container first, record the mass and then pour the dried silica gel into it. Label the the container with the dry mass. If you are using bags, stitch the bag closed first, then label the bag with the dry mass.

The last conditioning step is to add the right amount of moisture to the silica gel until the gel reaches the required moisture content. There are a couple of different ways to add moisture to the gel. The normal way is to set the RH of the conditioning chamber to the RH of the constant environment it will be buffering (ex. if the gel is being used to buffer an environment at 50%, set the conditioning chamber to 50% RH). Then thinly spread the silica gel into the chamber and leave it in, checking it periodically until the mass of the gel stops changing. Depending on how thick the layer of gel is, the amount of stirring that is done, and the screen-mesh size of the pan, the time it takes to condition the gel will vary. This process should take about 2-3 weeks, but using a fan can help to speed up the process.

There are rapid conditioning techniques that can take up to 2-3 days, instead of 2-3 weeks. One way is to place the silica gel into a moisture sealed container and run a humidifier on full capacity. This will create an environment with a 95% RH and the silica gel should absorb the moisture readily. A problem with doing this is overshooting the needed EMC, adding too much moisture. Another way to quickly add moisture to the silica gel would be to spray it with water. Doing this however, is not very accurate as it would be easy to over spray the top layer and under spray the concealed bottom layer. Decrepitation would also become a risk, as adding too much water would cause the gel crystals to breakdown and crack.

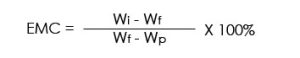

To make sure the conditioning has been carried out properly, taking samples of the silica gel and measuring the EMC is important to ensure that it has the cor

rect moisture content. To measure the EMC, there are instruments available that can give out direct readings, but there are ways to figure it out without these instruments. To calculate the EMC, first you need to heat up a hot plate until it reaches 250ºC, taking around 30 minutes. Put 20-30g of conditioned silica gel into a polyethylene bag and record the time the gel was taken out of the chamber and what conditions have been used to condition the gel. To ensure an accurate reading, prepare 2 samples at once. Pre-weigh 2 pans, record the weight and then put a 10g sample of silica gel into each of the pans. Label and re-weigh each pan. After you have done this, place the pans on the hot plate and weigh them at 10 minute intervals until the pans both stop changing their masses. Weigh the final mass. After gathering these pieces of information, it is possible to calculate the EMC, using this formula:

Wi= weight of condition gel & pan

Wi= weight of condition gel & pan

Wf= heated gel & pan

Wp= empty pan weight

After ensuring that the moisture content is correct, the silica gel is ready to be used and can be placed into the display case that it is buffering. When the micro climate indicates that the RH has changed more than it should have, then check the silica gel using the same method described above to find out the EMC and to recondition it. The silica gel should not need to be replaced more than twice a year, and if it is more than that, then a re-examination of the display case is needed to make sure it is well sealed. An examination of the disposition and quantity of the gel is also suggested if it has to be replaced frequently.

Works Cited

Canada. Canadian Conservation Institute. Environment and Deterioration Research Division. Silica Gel. By Raymond H. Lafontaine. Vol. 10. Ottawa, Canada: Canadian Conservation Institute, 1984. Print.

Stolow, Nathan. “Silica Gel and Related RH Buffering Materials, Conditioning and Regeneration Techniques.” Care of Collections. By Simon J. Knell. London: Routledge, 1994. 93-100. Print.